Advanced Manufacturing and Fabrication Studio

The Advanced Manufacturing & Fabrication Studio

Located in the larger section of Room 0901, this studio contains the most advanced equipment available in the Innovation Studio. Giant laser cutters, a full MIG/TIG welding booth, a CNC metal mill, and an upcoming metal laser are all featured here for students to learn and use with proper protective equipment. This space is heavily used for Engineering Capstone, a year-long project done by teams from all of the senior class that encompasses all fields of engineering.

Because this studio has the most powerful equipment, it also requires the most personal protective equipment. Everyone is required to wear eyeglasses while in the studio, and welding adds further safety attire through welding vests, jeans, gloves, and an advanced helmet visor that mitigates UV exposure.

The welding booth supports both MIG and TIG welding on materials like steel and aluminum. Using high voltages and intense heat, electricity melts metal that either flows through the tubing or is put alongside the torch to combine metal objects together and form a permanent joint, one of the strongest connections available in all of engineering.

A view of the welding booth’s interior, complete with clamps, brushes, high-powered air vents, and electricity grounding.

A crucial skill for manufacturing plants and automotive applications, welding expertise is one of the best ways to compliment an engineering degree.

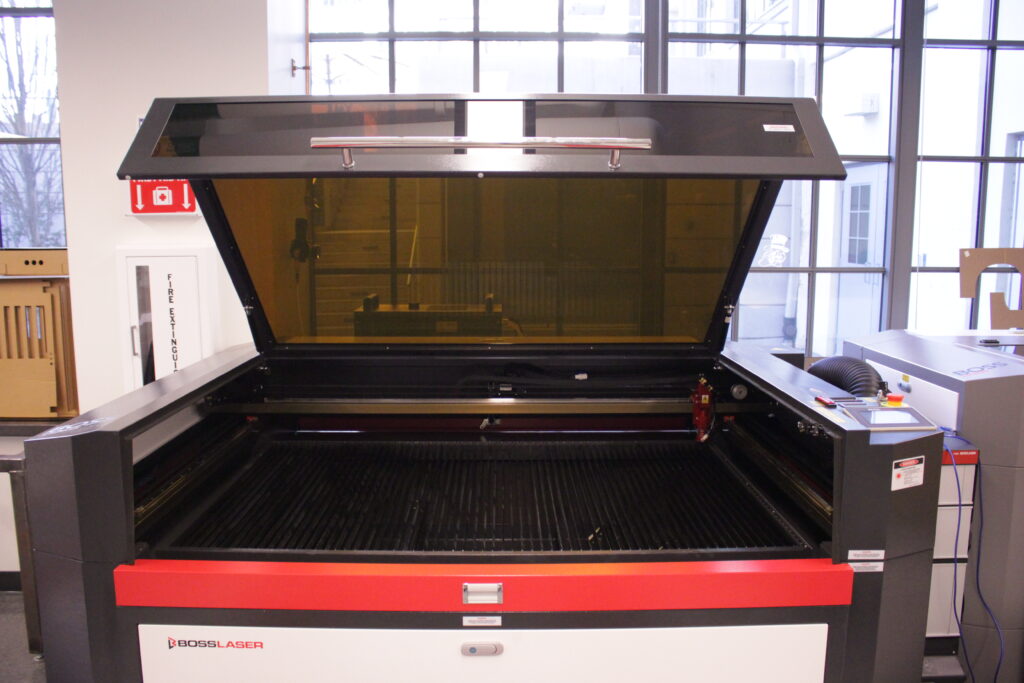

These two laser cutters can cut and engrave paper, cardboard, wood, acrylic, glass and many more materials. This type of manufacturing is called subtractive manufacturing, as opposed to 3D printers which are additive.

The larger of the two can cut materials greater than three feet long. The cover prevents eye exposure to the laser’s UV rays, and there’s both a filter and cooler to maintain safe conditions when cutting.

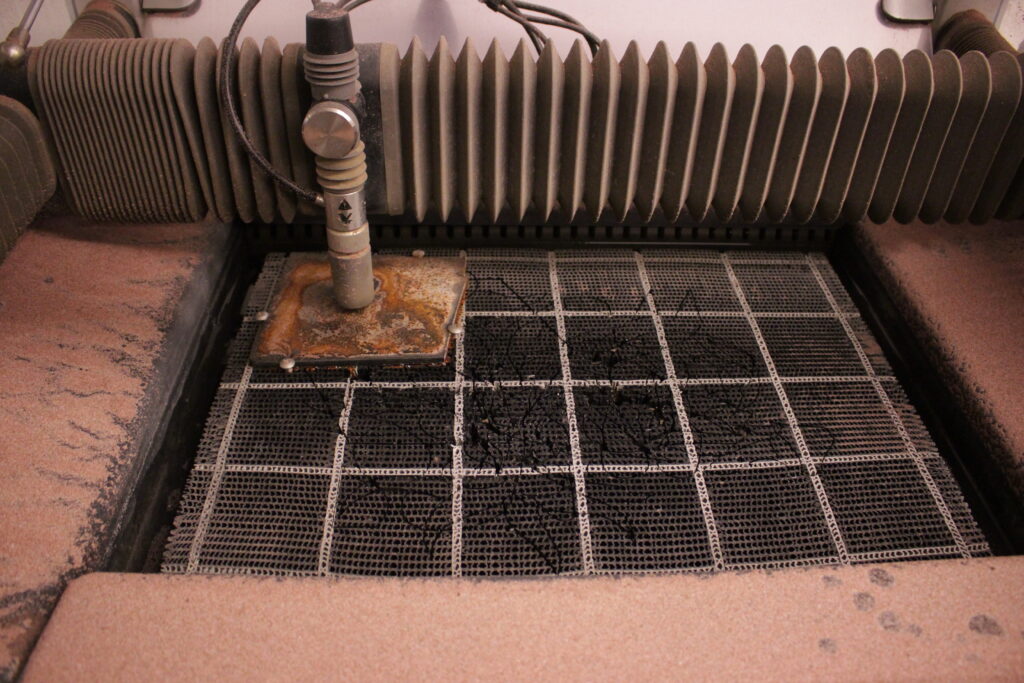

The Wazer water cutter uses highly pressurized water jets to cut through metals.

Like the laser cutter, it can create incredibly intricate 2D patterns and cut-outs.

The PCNC 440 CNC is able to mill metal, great for fashioning automotive parts.

This horizontal band saw can cut right through many materials, including metals.

The sand blaster allows parts to be smoothed, such as newly welded joints. It’s gloves allow for precise manual manipulation of the parts during smoothing.

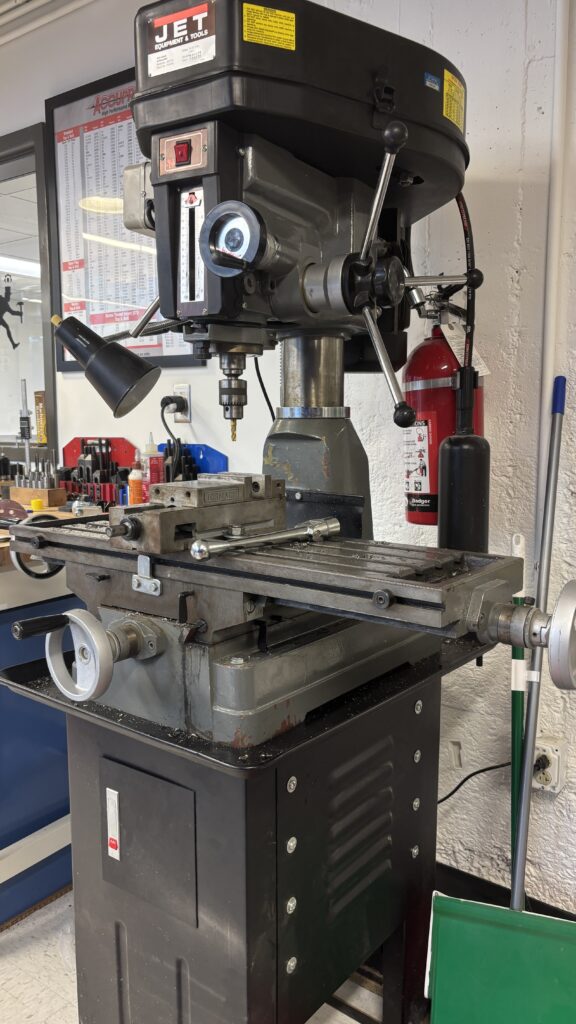

This knee mill allows manual machining of many different materials, including metals. It features user control of the x, y, and z directions.

The pedestal grinder is able to sharpen parts and remove imperfections on hard materials.

The metal break (left) and tubing bender (right) allows for the bending and forming of various metals in different shapes. The metal break focuses on sheet metal manipulation, while the tubing bender can manipulate metal pipes, rods, tubes, and other cylindrical shapes. Both are equally useful for engineering applications across all fields.